Reveal the Production of Braille Books in Centralised Braille Production Centre

Have you ever think of how a book full with drawings and text could turn into a braille book?

In the 1960s, braille production services were mainly provided by both the Hong Kong Education Bureau and the HKSB. As recommended by a government-delegated focus group on braille production, all braille should be produced by one centralised agency, thus the HKSB was appointed by the government to produce all braille materials for the blind in Hong Kong from 1986. Let’s follow Lynda Chung, Supervisor of Centralised Braille Production Centre (CPBC) to sneak peek the production of braille book!

1.Book Cutting

We will cut the spine of the book to make sure for smooth scanning of the pages.

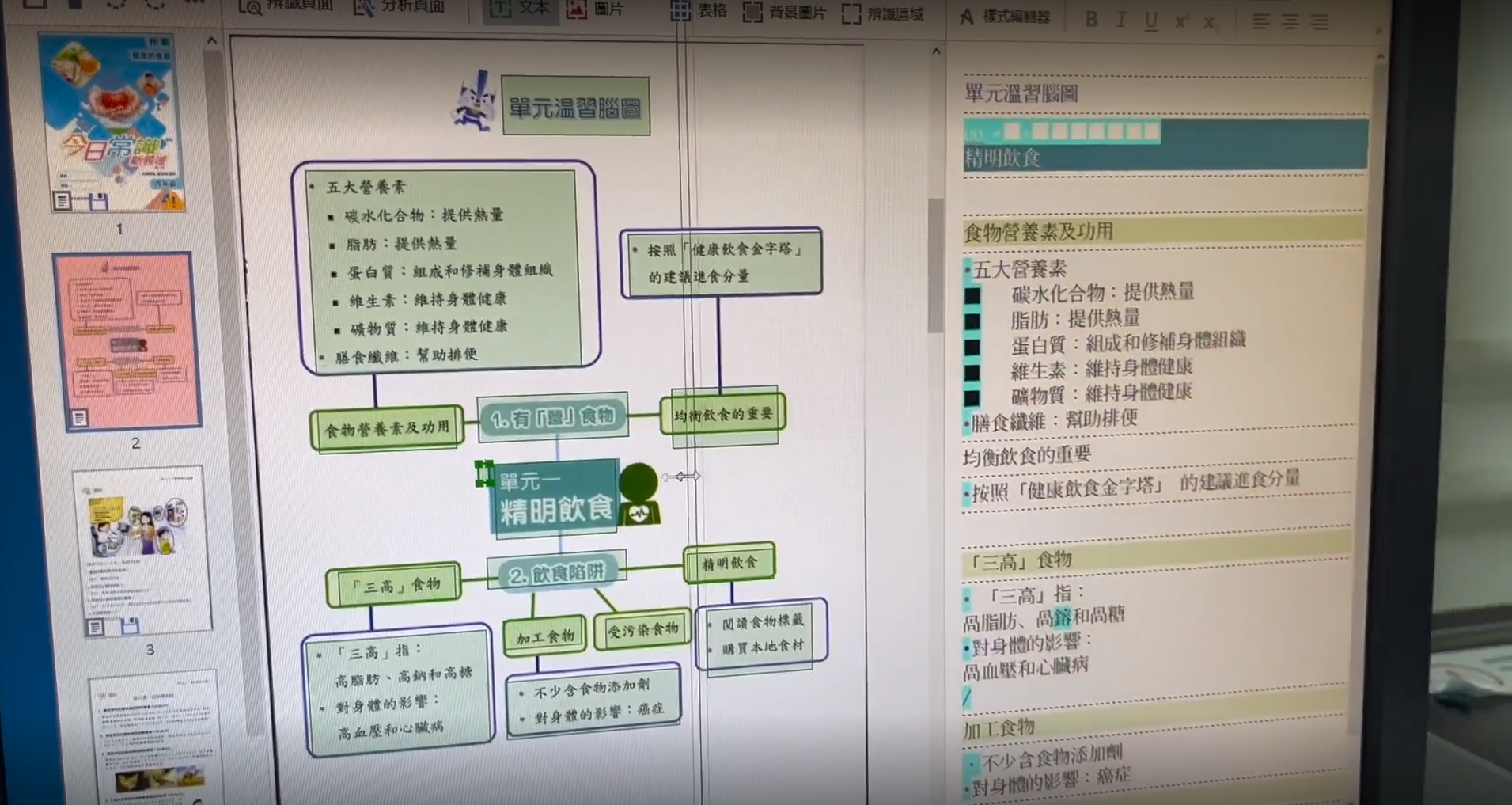

2.Text identification

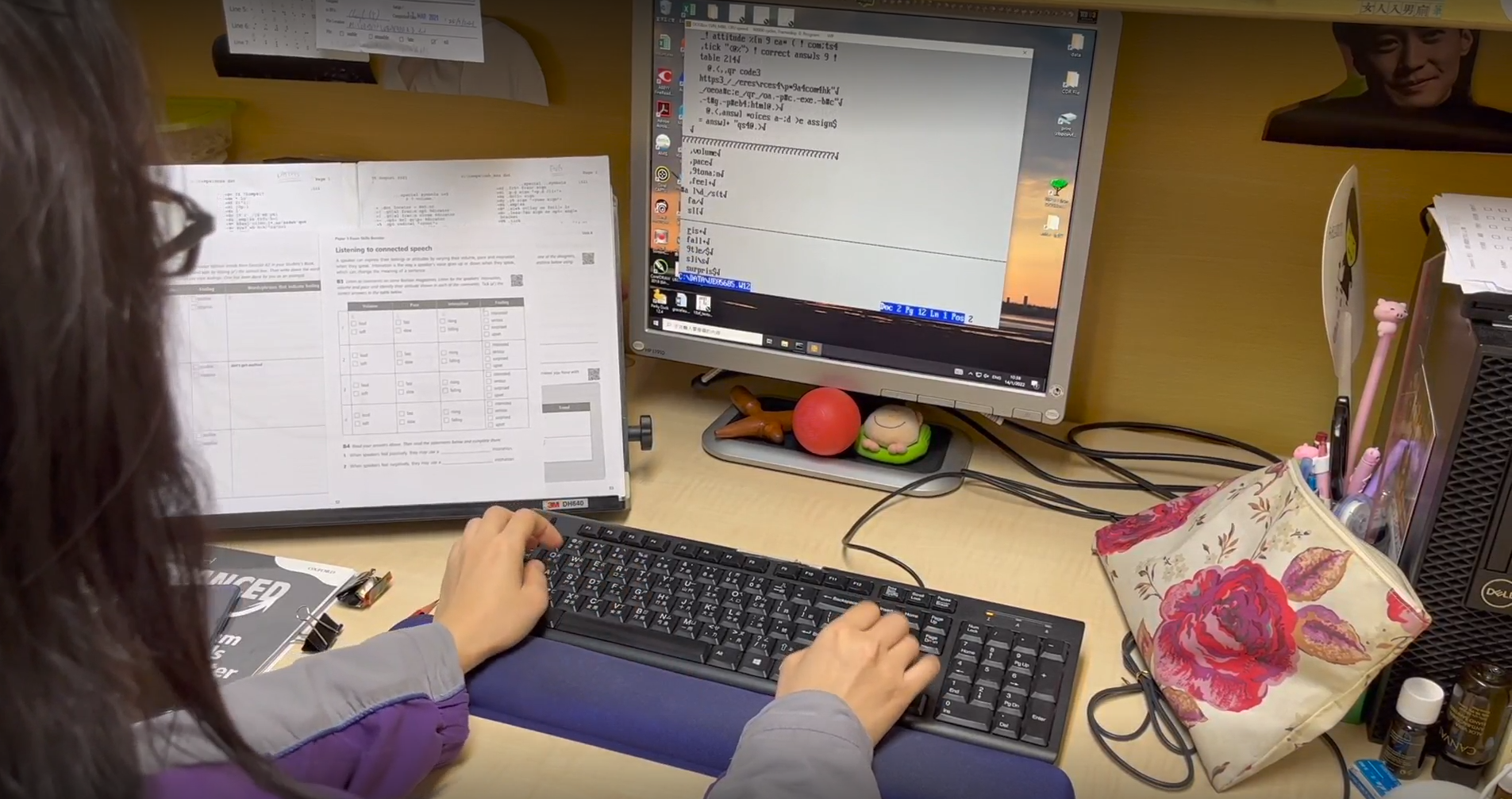

This is the key process for the whole production, as Lynda said that the order of reading the text would be framed by staff and let the text identified by the software. But due to the restriction of the software, we still need to manually check up on all the pages’ output file to avoid typos and garbled code. Without our colleagues’ detail check-up, the production afterwards would be seriously affected!

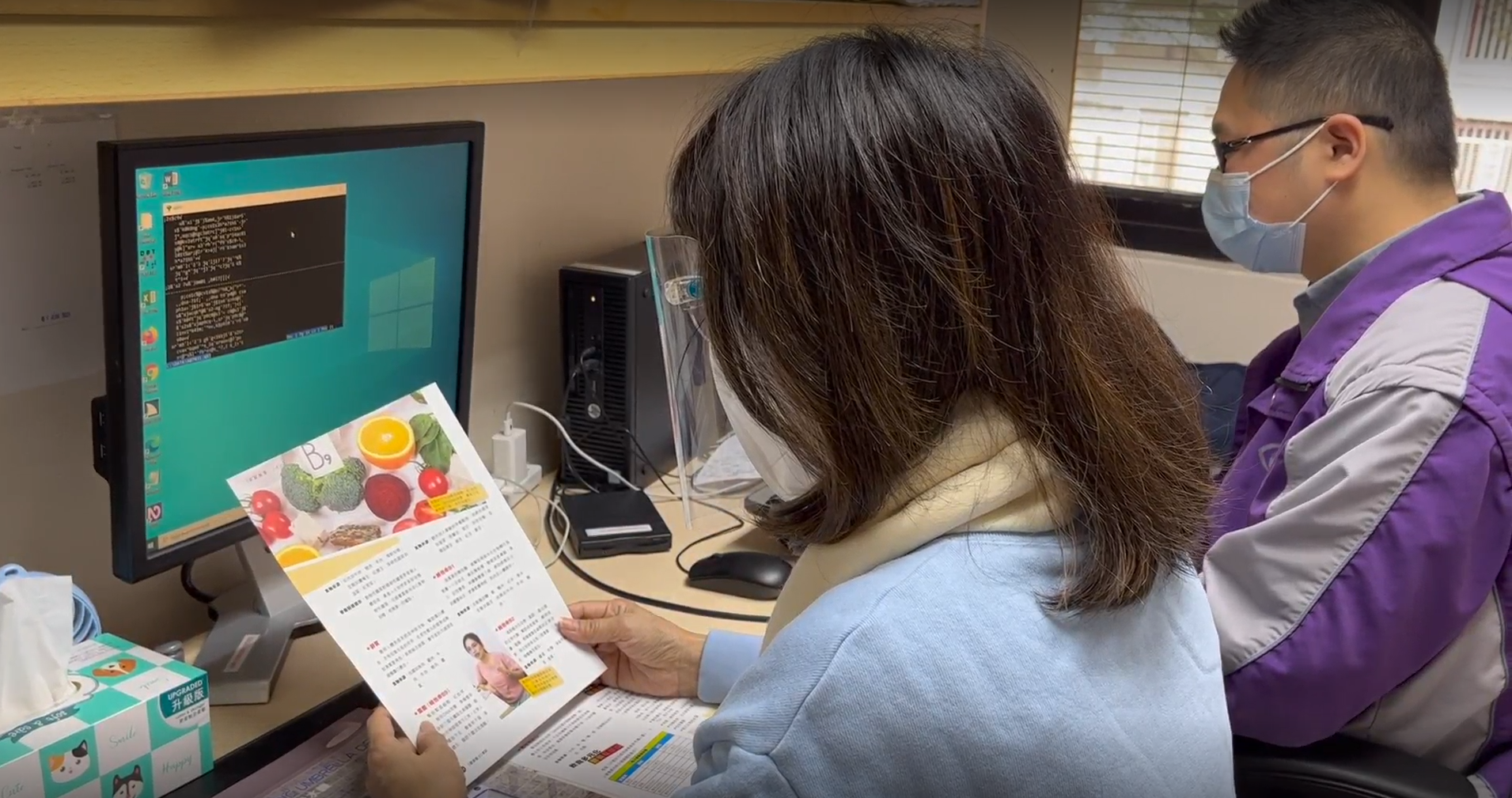

3. From text to braille

After proofreading of the whole book, the file will be transcribed into braille code by software initially. Then we let the colleague with braille knowledge to typeset and re-proofread the file in a braille mindset. If it is in charged by a visually impaired colleague, we would invite volunteer to read out the content, so that VI colleague could “touch” and edit the content through braille display device. It requires teamwork but a one click button on the computer to ensure the quality of the book. After Covid time, we need more volunteers to work from home to read through online meeting call for assistance.

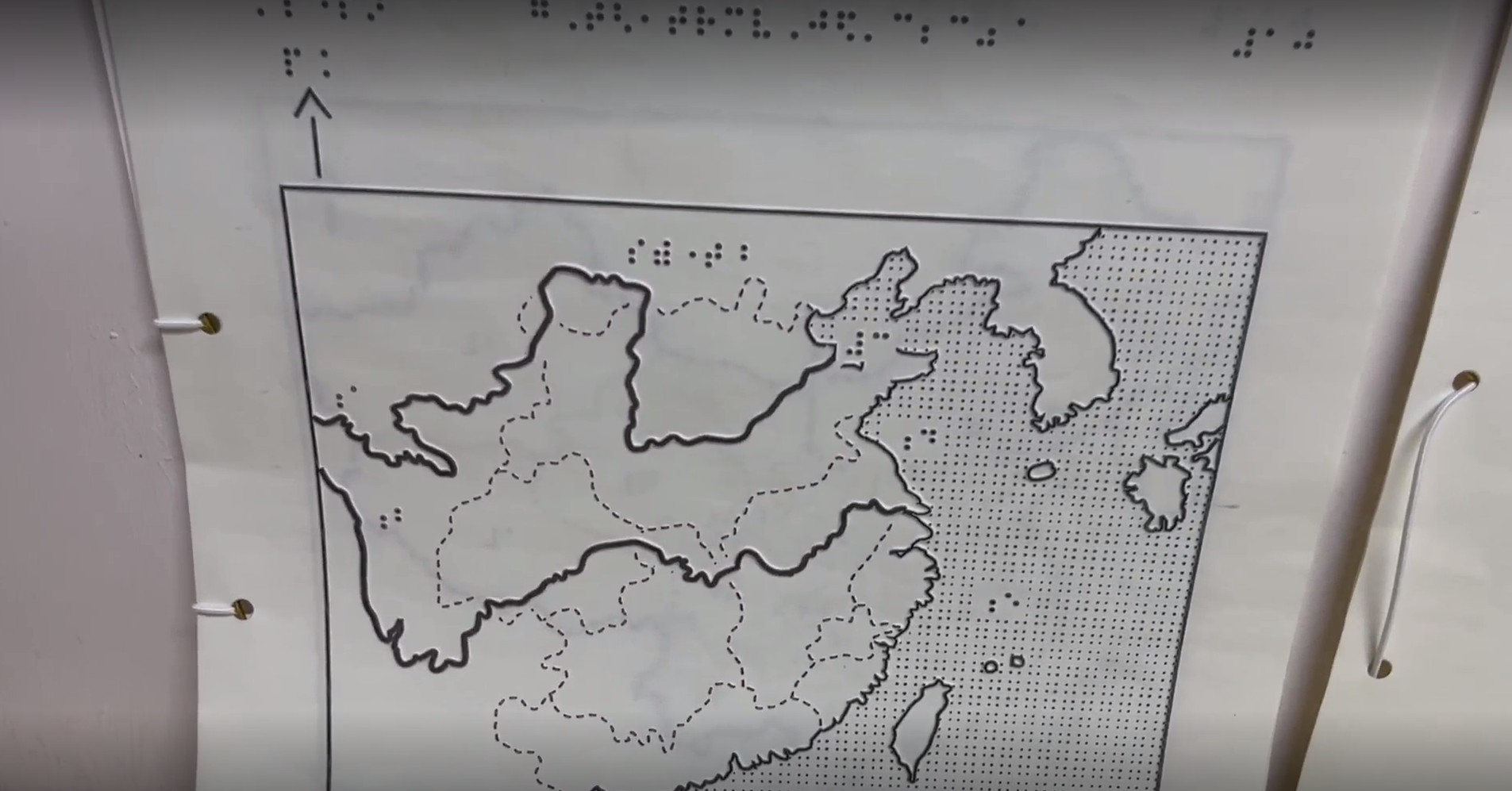

4. Tactile diagrams

There are a lot of diagrams inside a textbook usually. We used one of the tactile printing machine to print tactile diagrams by difference of grayscale intensity of the original graphics. This usually applied to those mathematics’ graphics. We use a special heater to print others diagrams, like map or human anatomy/structure. The printed diagram is passed through the device which causes the black ink to swell and form the end product of a diagram which can be examined using hands.

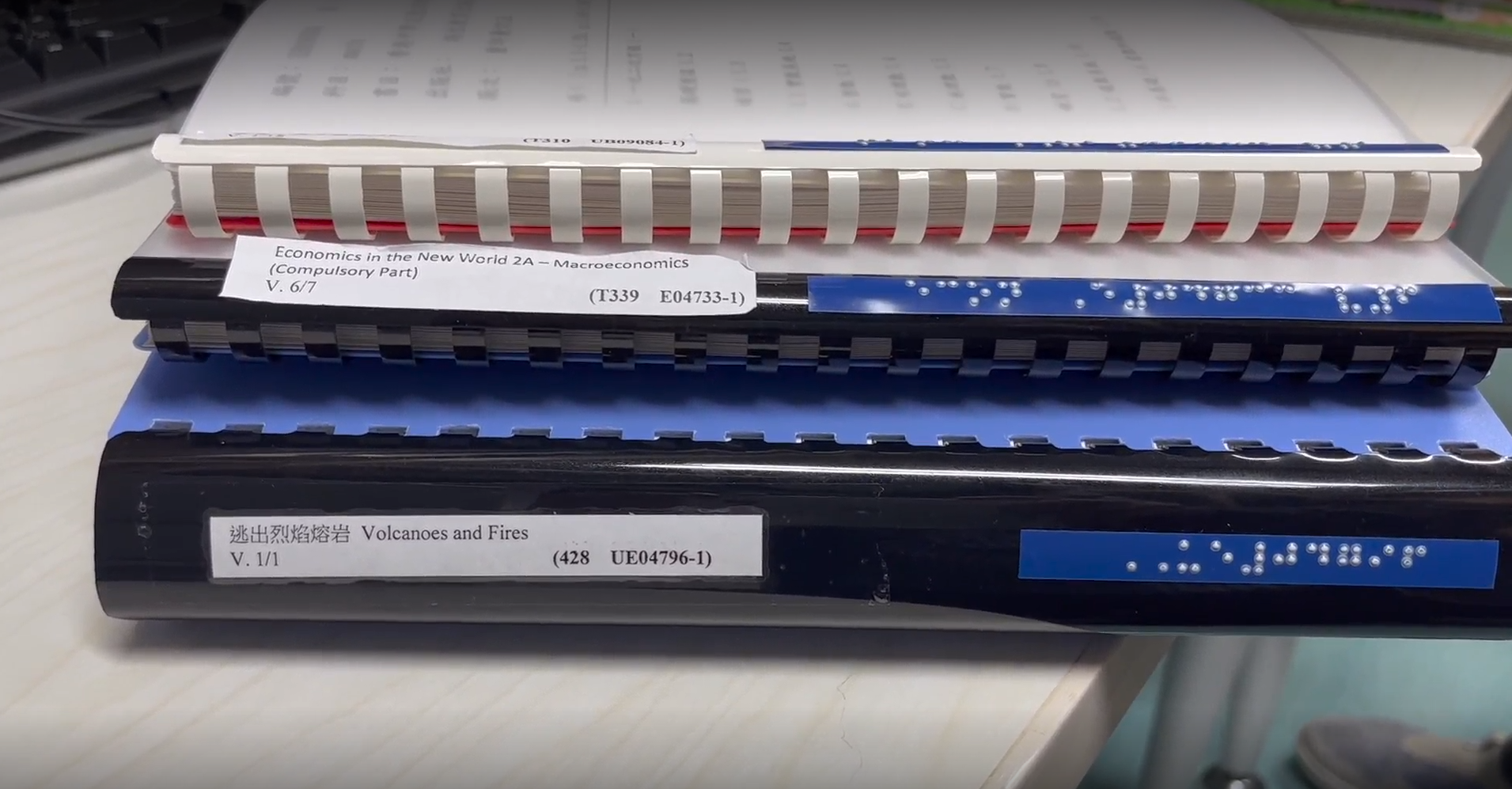

5. Printing and Binding

It’s the time to print the book after all the process! Unlike normal text that could adjust font size, braille is standard in size. Let’s take a primary mathematic textbook with a lot of diagrams as example, it may end up in 8-10 volumes; a secondary mathematic book could turn into 40-50 volumes. There are 4 big scaled braille printer in CPBC mainly with few small scaled printer for exam paper and children’s book. The printing quantities is around 550,000 papers annually for textbooks, newspaper & journals inside library; the binding of books is around 4000-5000 titles. So you could hear “beeping” sound inside CPBC every day! And do not underestimate this number! This put big pressure on the maintenance of the braille printer, which is very rare in Hong Kong since we are the main user. We need to pay great effort for the worst scenario.

Lydna said July and August are the peak season for CPBC as need to prepare quality braille text book before the new term of school in September. She hoped the public could understand more about the operation of CPBC so that could support this work of selfless social contributions to our visually impaired students!

Our Stories

Our Stories Photo / Video

Photo / Video